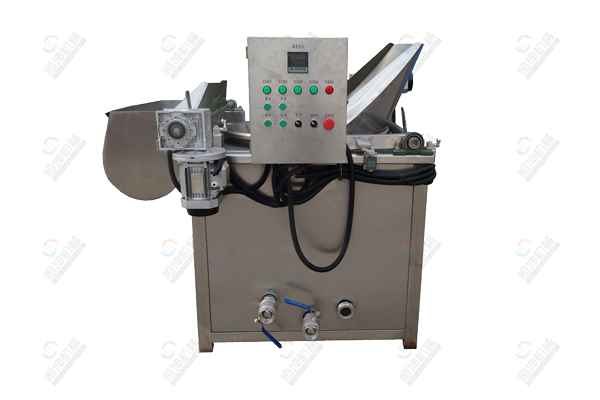

Deep fryer

A new generation of products with high efficiency and practicality, as well as affordable prices, featuring fully automatic frying machines; Capable of automatic feeding and discharging, with a design of stirring...

- 电话:+86 15094998991

- 固话:0536-3190033

A new generation of products with high efficiency and practicality, as well as affordable prices, featuring fully automatic frying machines; Capable of automatic feeding and discharging, with a design of stirring and oil-water separation, it is currently one of the most practical equipment in deep frying;

1. Heating method: Closed loop heating method is adopted, and various energy sources such as gas and electric heating can be selected.

2. Function: It can achieve full automation and continuous work from raw material input to finished product, including continuous frying, online oil filtration, oil removal, cooling, and powder mixing (additive mixing).

3. Features: High degree of automation, low labor intensity, labor-saving, and high labor efficiency.

4. Application; Deep frying of meat such as chicken fillet, fruit pulp, chicken chops, meat chunks, and tenderloin; Fried snack food such as small Fried Dough Twists, crisps and chips; Deep frying of dried fruits such as peanuts and fava beans;

5. Advantages: Frying materials with automatic temperature control device and automatic discharge. The fryer comes with products (heat exchanger, pipeline, circulation pump three, coarse filter machine, fineness machine, oil storage tank, automatic oil pump). The materials used for frying are fully immersed in oil, with a full flavor and the frying time can be adjusted at will.

This fryer is also suitable for continuous frying production lines; Basic production process: raw material lifting → vibration leveling → frying → oil pouring → conveying and lifting → material storage tank → oil removal → conveyor → vibration leveling machine - middle elevator - seasoning machine - drum - conveying